Comparison of energy consumption between Changweifu Road centrifugal compressor and screw compressor

The design life of centrifugal air compressors is more than 20 years (international standard), and maintenance and inspection are required every 8000 hours. If customers reserve maintenance time every year, they can consider not setting up a backup machine. Compressed air does not contain oil, and after long-term use, the performance of centrifugal air compressors can be improved to the level of new machines after major repairs;

1、 Air compression process

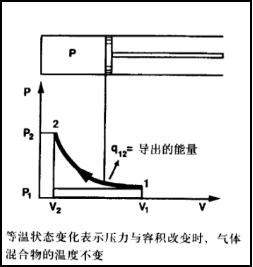

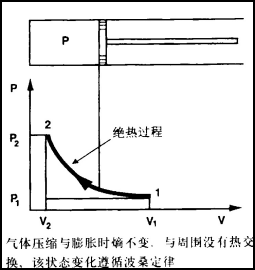

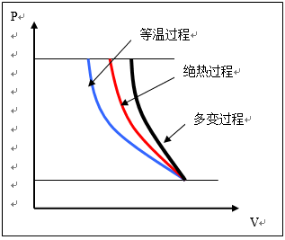

Air compression, three states: 1. Isothermal compression; 2. adiabatic compression; 3. Variable compression; According to the principle, isothermal compression is the most energy-efficient compression method for gas compression.

The variable process includes processes of complete heat exchange with the surrounding environment and processes without heat exchange. In fact, this includes all processes and is a universal practical process.

Diagram of energy consumption relationship for three main processes:

As shown in the diagram, isothermal compression work

2、 Compressor Overview

Screw compressors are positive displacement compressors, usually divided into micro oil screw air compressors and oil-free screw air compressors according to whether the coolant participates in the compression process.

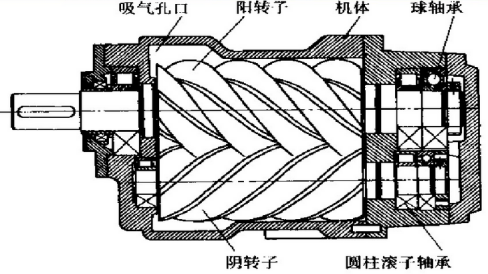

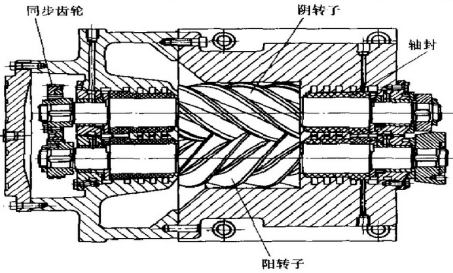

Schematic diagram of micro oil screw machine head

Micro oil screw air compressor is close to isothermal compression due to the involvement of coolant in the compression process, with high efficiency but oil content in the compressed air;

Schematic diagram of oil-free screw head

The compression process of oil-free screw air compressor does not involve coolant and is close to a variable compression process, with low efficiency, but the compressed air does not contain oil;

Application scope description: In situations where oil-free air is strictly required, customers usually have to consider choosing oil-free screws with high energy consumption, while micro oil screws are more widely used.

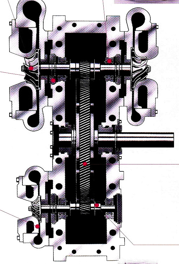

Centrifugal air compressor is a power compressor, and the principle is that compressed air is oil-free, and the compression process is an isothermal compression process;

Horizontal sectional diagram of centrifugal air compressor head

Schematic diagram of titanium alloy impeller for Changwei centrifugal compressor

3、 The selection of compressor mainly considers several factors

1、 Price demand;

2、 Quality requirements;

3、 Service demand;

1. Price requirements include both procurement costs and implicit energy consumption costs; With the further exploration of the overall price of centrifugal air compressors, it has provided the possibility for a wider range of applications of centrifugal air compressors;

Note: In terms of energy consumption, there is a comparison between screw compressors and centrifugal compressors, with oil-free screwsThe highest, usually over 20% higher; Micro oil screw and centrifugal compressor are usually 30m3/Min is the boundary, usually flow rateLess than 30m3/min, Micro oil screw has high efficiency,30m3/Min micro oil screw and centrifugal compressor are level, with a flow rate greater than 30m3/min, The centrifugal compressor has high efficiency; (Note: Due to structural reasons, screw compressors cannot achieve lower exhaust pressures.)Within 4 kilograms,Centrifugal compressors generally have high efficiency

Example: Customer needs45Nm3/min,0.8MPaG air compressor, micro oil screw air compressor with energy consumption of 330KW, purchase price of 450000 yuan; Centrifugal air compressor 300KW, 700000 yuan, combined with energy consumption and the complex oil containing compressed air treatment system of micro oil screw, as well as the negative production impact that oil may bring, choosing centrifugal air compressor has now become the preferred choice for customers.

2. Quality requirements:

Design life of screw air compressorAround 10,everyMaintenance is required after 2000 hours, and for production safety, a backup machine is usually set up, and the compressed air contains oil; Due to the severe decline in performance, most customers cannot tolerate the continued use of a 10 screw air compressor.

Design lifespan of centrifugal air compressorlifeOver 20 years (international standard), maintenance and inspection are required every 8000 hours. If customers reserve maintenance time every year, it may be considered not to set up a backup machine. Compressed air does not contain oil, and after long-term use, the performance of centrifugal air compressors can be improved to the level of new machines after major repairs;

Note: Based on the above characteristics, we believe that customers will make their own choices.

3. Service requirements

3.1The serviceability of the machine itself

A centrifuge is a high-speed, high-precision, and highly reliable machine, and service personnel must undergo professional training to be competent in on-site maintenance and inspection work. Usually provided by professional service engineers from suppliers, it is relatively worry free for customers.

The oil-free screw head is a trade secret and no one is allowed or authorized to repair or inspect the head. Any abnormalities in the head must be returned to the manufacturer or repaired or updated abroad, and the repair cycle is relatively long.

Micro oil screw requires2000 hours of maintenance, tedious work;

3.2. Service fees incurred

The annual maintenance of oil screws is tedious and expensive, and specialized lubricants are the root cause of the huge cost of screw air compressors;

The daily service fee for oil-free screws is not high, butThe maintenance of the machine head for 5-8 years requires returning to the factory, which is a huge cost, usually more than 40% of the procurement cost. Many customers cannot tolerate it and directly purchase new machines;

Centrifugal air compressor operationStable, only requires routine maintenance, pay attention to purchasing some parts for emergencies, and the cost is very low. The service integration concept of Changweifu Road centrifugal air compressor isOne of the distinguishing aspects of centrifugal air compressors from all other brands is the service integration concept, which enablesweBecome the brand with the lowest after-sales service cost in the industry.

Experience tells us that the comparative relationship between service fees is usually:

Oil screw≥Oil free screw≥Centrifugal air compressor

four.Several Misunderstandings in Compressor Selection

1.The screw air compressor is easy to adjust the air volume, while the centrifugal air compressor is inconvenient to adjust the air volume;

Screw air compressor is a positive displacement compressor. During the process of adjusting the air volume, the energy consumption remains unchanged. A slightly wider adjustment range requires the use of a frequency converter to adjust the screw speed;

Centrifugal air compressor is a power compressor that can adjust the flow rate through inlet throttling, with a wide range of adjustments(30%The energy consumption fluctuates accordingly;

Note: The reason for this erroneous concept is due to insufficient understanding of the principle of the compressor;

2.Screw air compressors can be frequently started and stopped, while centrifugal air compressors cannot be started and stopped frequently;

Frequent starting and stopping of centrifugal air compressors is not prohibited from the principle of the compressor. In other words, some brands of centrifugal air compressor gearbox structures (including selected seals and bearings) are not suitable for frequent starting and stopping, while some brands of centrifugal air compressor gearbox structures are suitable for frequent starting and stopping.

Of course, the motor starter cabinet also has a requirement for the number of on-off cycles due to heating.

Note: The reason for this erroneous concept is due to insufficient understanding of the structure of centrifugal air compressors;

3.Screw air compressors are suitable for situations with small air flow, and centrifugal air compressors should be more economical with larger pressure;

The small amount of "stinginess" needs to be quantified, and some customers require it60-70m3/minWe may consider using a screw air compressor, but our suggestion is that if oil-free compressed air is needed, no matter how small it is(12.5m3/minthe above)Both can consider centrifugal air compressors, and if oil containing compressed air is acceptable40m3/minAbove, centrifugal air compressors can be given priority consideration.