Key points for selecting centrifugal air compressors

The compressed air required by customers is usually provided by air compressors, which are usually divided into two types: volumetric and power compressors. Piston air compressors and screw air compressors belong to volumetric compressors, while centrifugal air compressors belong to power compressors.

The compressed air required by customers is usually provided by air compressors, which are usually divided into two types: volumetric and power compressors. Piston air compressors and screw air compressors belong to volumetric compressors, while centrifugal air compressors belong to power compressors.

Centrifugal compressors, due to their oil-free nature, can independently adjust the air volume (controlled by the inlet guide vanes to regulate the compressor's processing air volume), resulting in high efficiency. With the popularization of centrifugal compressor technology, they have gained increasing recognition from a wide range of users.

The centrifugal air compressor we produce has a flow rate of 12m3/For models above min, there are suitable models for users to choose from, and selecting appropriate parameters is crucial to ensure that the selected centrifugal compressor scheme meets project needs. For example, if the flow rate of the compressor is too low or too high, or the exhaust pressure is too high or too low, it will have an impact on the project. We provide the following suggestions for reference when determining compressor parameters.

Parameter selection table

|

It is necessary to have a clear understanding of the flow and pressure fluctuations on the production site in order to select the appropriate centrifugal compressor scheme. |

|||

|

Daily production gas consumption |

|

Daily production gas point pressure |

|

|

Peak gas consumption during production |

|

Distance from the farthest gas point to the compressor (evaluating pipeline pressure loss) |

|

|

Gas consumption during low production periods |

|

Pressure loss of post-processing device |

|

|

Are there any drastic changes |

|

The allowable pressure fluctuation range of the pipeline network |

|

Note: The owner's equipment engineering team will gather information on the gas requirements for the project and discuss and confirm the compressor solution with our sales personnel during the process of communication.

Explanation of self flow regulation method for centrifugal compressor

During the production process of customers, there are usually fluctuations in the demand for compressed air, which requires air compressors to have automatic adjustment capabilities. Of course, customers hope that energy consumption will also decrease with the reduction of gas production.

For positive displacement compressors, the methods of air flow regulation usually include inlet throttling and speed regulation.

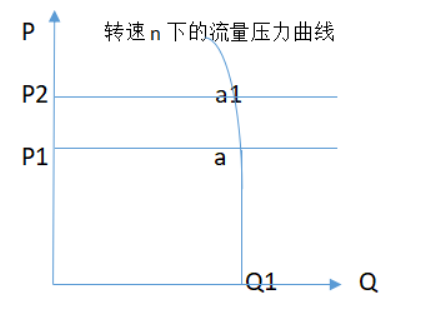

A positive displacement compressor is a device with constant flow rate and variable pressure. As shown in Figure 1, if the flow rate fluctuates slightly, the range of pressure fluctuations is relatively large. If the inlet throttling method is used to regulate the displacement air compressor, the exhaust pressure of the compressor will fluctuate greatly. Therefore, when customers purchase screw air compressors, they usually choose higher pressures, such as the actual required exhaust pressure of 0.6MPaG. However, they may purchase 0.8MPaG screw air compressors to meet the needs of flow regulation.

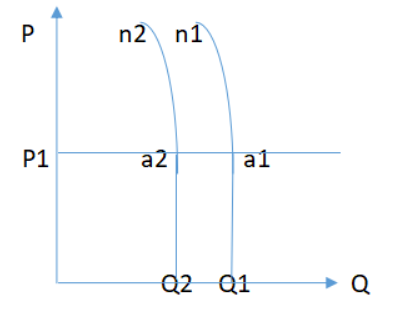

Rotational speed is an important parameter of a positive displacement compressor, and using variable frequency and variable speed regulation is the most effective way to adjust the positive displacement compressor, as shown in Figure 2. By adjusting the rotational speed from n1 to n2 (decreasing the rotational speed), the pressure remains constant and the flow rate decreases, achieving the ideal regulation purpose. At different speeds n, corresponding to different flow pressure curves, the flow rate increases or decreases while the pressure remains constant. However, due to the limitations of the main motor, in reality, the speed range of the variable frequency is mostly between 40% and 100%, and it is not possible to achieve 0-100% adjustment.

|

|

|

|

illustration1(The flow rate fluctuates slightly, while the pressure fluctuates greatly) |

illustration2(Different speeds correspond to different flow rates, with constant pressure) |

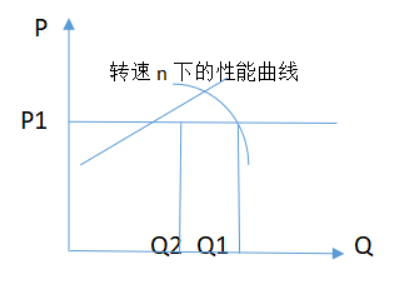

Centrifugal air compressor belongs to the equipment of constant pressure and variable flow rate, as shown in Figure 3. In principle, it is exactly in line with the customer's demand for constant pressure and variable flow rate. During the fluctuation of flow rate, the pressure remains constant. Therefore, the centrifugal compressor adopts the method of inlet throttling to adjust the exhaust volume, which can achieve the purpose of adjusting the flow rate.

|

|

|

|

Figure 3 |

IGV (inlet guide vane) |

Introduction to the principle of regulating air flow with guide vanes

As the inlet guide vanes rotate (adjusting the intake angle), the amount of air that the first stage compression impeller can suck in also changes, usually achieving a flow adjustment range of 70-100% (between Q1 and Q2, automatically adjusted by IGV). The current value of the main motor also changes with the flow rate. During the adjustment process, the exhaust pressure remains constant. If the user's air volume decreases below 70% of the design flow rate (flow rate less than Q2), the BOCV (proportional vent valve) will open to release excess compressed air proportionally, achieving the goal of constant pressure. Usually, centrifugal air compressors controlled by IGV (inlet guide vane) and BOCV (Blow off control vane) can achieve automatic intelligent regulation of flow rate from 0 to 100%.

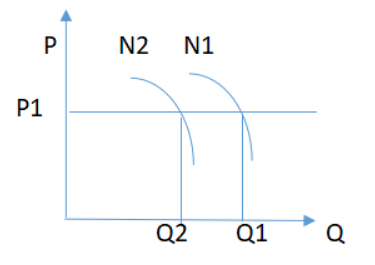

Speed is also an important core parameter of centrifugal air compressors. Variable frequency (variable speed) regulation, in principle, is also suitable for centrifugal air compressors. At different speeds, the corresponding performance curves are different. Combined with requirements and pipeline characteristics, it can achieve the function of regulating variable flow rate and constant pressure or variable pressure and constant flow rate. As shown in Figure 4

Figure 4

However, for a fully assembled gear speed increasing centrifugal air compressor that can easily achieve automatic flow regulation of 70-100% through the inlet guide vanes, variable frequency speed regulation is unnecessary. In summary, due to the principle of compressors, variable frequency speed regulation is the most effective load adjustment method for positive displacement compressors, while inlet guide vane regulation is the most effective adjustment method for integral gear speed increasing centrifugal air compressors.